|

Ningbo Beilun Fully Machinery Co.,Ltd.

|

Servo motor&energy saving injection mold machineServo

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

The intergrated double drive cylinder injection system with symmetrical oil circuit can ensure the injection stable and precise.weldless oil circuit

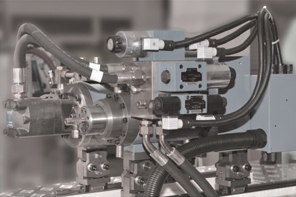

Hydraykuc System

Rexroth valves are to ensure quick response and high precision.Plus optional MOOG or Rexroth servo valve,your desire of perfect molding becomes true.

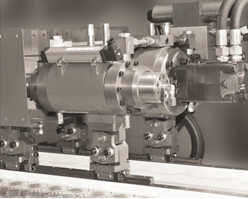

Injection Unit

The intergrated double drive cylinder injection system with symmetrical oil circuit can ensure the injection stable and precise.weldless oil circuit provides high speed and high pressure.Linear guide bearings control friction within the minimum resistance.

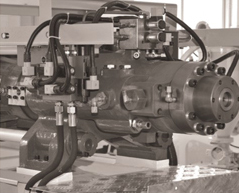

Direct Clamping System

Patented direct clamping system,distinguished as high pressure,efficient,and energy saving,can realize 680 mm/sec.fast mould close/open and perfect low pressure mould protection.

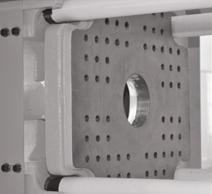

Platen Design

Advanced platen design,big platen space&stroke and European standard platen screw hole,can satisfy your various needs.Mininal platen distortion tolerance ensures perfect molding.

| INJECTION UNIT | JH 50 | ||||

| Screw specification | A | B | C | D | |

| Screw diameter (mm) | 22 | 25 | 28 | 32 | |

| Screw stroke (mm) | 130 | 130 | 130 | 130 | |

| Screw L:D(L/D) | 24 | 23 | 20.5 | 18 | |

| Shot volume (cm³) | 49 | 64 | 80 | 104 | |

| Injection rate(g) | 44 | 57 | 72 | 94 | |

| Ⅱ | Injection pressure(Mpa) | 278 | 215 | 171 | 131 |

| Dwell pressure(kgf/cm²) | 2832 | 2193 | 1749 | 1339 | |

| Injection speed(mm/sec) | 218 | 210 | 210 | 210 | |

| Injection rate(cm³/sec) | 82.8 | 103 | 129.2 | 168.8 | |

| Screw rotate speed (rpm) | 310 | 310 | 310 | 310 | |

| Ⅲ | Injection pressure(Mpa) | 215 | 166 | 133 | 102 |

| Dwell pressure(kgf/cm²) | 2191 | 1696 | 1352 | 1035 | |

| Injection speed(mm/sec) | 282 | 350 | 350 | 280 | |

| Injection rate(cm³/sec) | 107.1 | 137.4 | 172.3 | 225.1 | |

| Screw rotate speed (rpm) | 310 | 310 | 310 | 310 | |

| Nozzle sealing force(KN) | 19.8 | ||||

| Nozzle advance stroke(mm) | 50 | ||||

| Heater power (KW) | 4.25 | ||||

| CLAMPING UNIT | |||||

| Clamp force (KN) | 500 | ||||

| Opening force (KN) | 42.9 | ||||

| Platen stroke (mm) | 450 | ||||

| Space between tie bars(mm) | 370x320 | ||||

| Max.mold height(mm) | 600 | ||||

| Min.mold height(mm) | 150 | ||||

| Ejector number(pc) | 1 | ||||

| Ejector force (KN) | 32.4 | ||||

| Ejector stroke(mm) | 95 | ||||

| OTHERS | |||||

| Special pump pressure(Mpa) | 25 | ||||

| Standard pump pressure(Mpa) | 21 | ||||

| Machine dimensions(LxWxH) m | 11 | ||||

| Pump motor power(KW) | 4.00x1.00x1.65 | ||||

| Machine weight(T) | 3.4 | ||||

| Oil tank capacity(L) | 175 | ||||

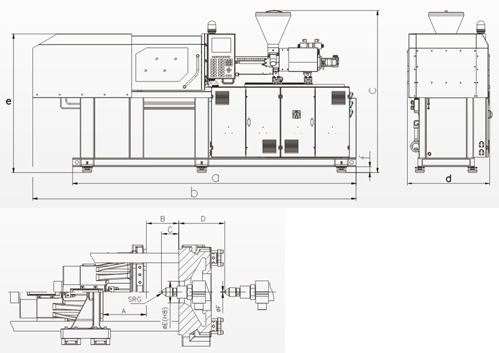

| A | B | C | D | E | F | G | a | b | c | d | e | f | |

| JH50 | 450 | 150 | 50 | 290 | 100 | 3 | 10 | 3700 | 4100 | 1900 | 980 | 1650 | 70 |

Noise generated abnormal noise, said parts damaged or improperly adjusted, should follow the noise and find out the reason of instant repair position.

1, when the hydraulic oil injection in the chassis, the pump suction air or oil filter dirt blocking will cause the oil pump oil shortage, caused by bubbles in the oil discharge impact noise generated by the blade, the solution is to check the amount of oil, to prevent inhalation of air and clean the oil filter.

2, the hydraulic oil of high viscosity, increase the flow resistance, need to replace the hydraulic oil suitable.

3, because of damage to the pump or motor bearing or blade, coupling concentricity deviation caused by noise, must adjust the concentricity and replacement of spare parts.

4, valve failure but still in the reaction function, such as the heart valve wear, leakage blocking, burr, movement is not flexible, solenoid valve because the current lack of failure will also generate noise. The solution is to clean the spool, spool wear should be replaced with new parts, current must be stable and adequate

5, hydraulic components damage and an oil pipeline blocking makes noise at high flow hydraulic oil.

6, mechanical fault, bearing wear or mechanical lack of lubricating oil or loose parts, should find out the reason to tighten or replacement parts, to ensure that there is enough oil.

Injection molding machine, injection molding machine or injection machine. It is the main forming equipment plastic products, thermoplastic or thermosetting plastics using plastic molding into various shapes. Divided into vertical, horizontal, all electric. The function of heating plastic injection, high voltage is applied to the molten plastic, so that the injection and full of mold cavity

Welcome to my company contact information