|

Ningbo Beilun Fully Machinery Co.,Ltd.

|

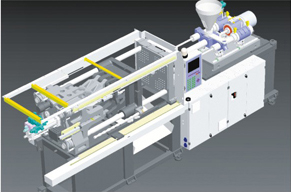

new design good quality cutlery plastic injection moulding machine

| Price: | 40000.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

| View the Video: |

|

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Power Saving Injection Moulding Machine

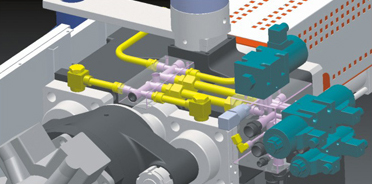

High percision clamping.

Low pressure mold protection

Thin wall plastic injection molding machine

Energy Saving Injection Moulding Machine

High percision injection, Low pressure mold protection, Well-Experienced Engineers, Timely Delivery

| GH170 | ||

| INJECTION UNIT | A | B |

| Sxrew diameter mm | 40 | 40 |

| Screw stroke mm | 200 | 150 |

| Screw L:D L/D | 25 | 25 |

| Shot volume cm3 | 251 | 188 |

| shot weight Ps g | 226 | 170 |

| injection pressure Mpa | 147 | 156 |

| dwell pressure kgf/cm2 | 1479 | 1584 |

| injection speed mm/sec | 270 | 280 |

| injection rate cm3/sec | 339.1 | 351.7 |

| screw rotate speed rpm | 400 | 400 |

| nozzle sealing force KN | 44.5 | 25.3 |

| nozzle advancestroke mm | 50 | 80 |

| heater power KW | 9.32 | |

| CLAMPING UNIT | ||

| clamp force KN | 1700 | |

| toggle steoke mm | 435 | |

| space between tie bars mm | 470×470 | |

| max.mould height mm | 500 | 500 |

| min.mould height mm | 180 | 180 |

| ejector number pc | 5 | |

| ejector force KN | 45.2 | |

| ejector stroke mm | 130 | |

| OTHERS | ||

| specialpump pressure Mpa | 21 | 23 |

| machine dimensions(L×W×H)m | 4.5×1.11×1.78 | |

| Machine weight T | 5 | 5.3 |

| oil tank capacity L | 250 | |

| pump motor power KW | 22 | |

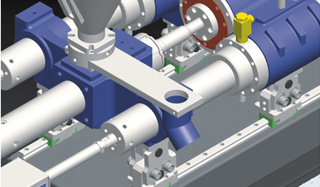

Company under the direction of development of plastic industry, with "high efficiency, low cost, energy saving, environmental protection" principle, launched a special speed thin-wall injection molding machine, deep cavity injection molding machine, injection molding machine hydraulic system is equipped with optimization, the injection speed is greatly improved, matching special rapid screw special, showing a plasticizing capacity high, two cylinder balance injection system improvement, high rigid locking structure to achieve the high requirements for life extension, mould, greatly improve the precision of products.

Injection molding machine, injection molding machine or injection machine. It is the main forming equipment plastic products, thermoplastic or thermosetting plastics using plastic molding into various shapes. Divided into vertical, horizontal, all electric. The function of heating plastic injection, high voltage is applied to the molten plastic, so that the injection and full of mold cavity

Welcome to my company contact information